Removable and fixed panels for thermal insulation

and/or fire protection to shield crititical parts

of the aircraft from heat and fire.

Engine components; exhaust, electrical and auxiliary services system or

structural elements, everything can be protected from fire and heat.

The shape and the fixing accessories are designed for optimal coupling with

the underlying component that has to be insulated, without interferences

with the surrounding elements, for a rapid assembly and disassembly.

The usage of blankets to assemble directly on the components, without welding,

permits a fast assembly cycle, useful especially for maintenance operations.

Typical materials:high performance insulation Microporous or

Aerogel type material. The best possible thermal abatement with reduced thicknesses.

The external metal cladding is constructed in sub-millimeter metal

foil: AISI 321 steel, Hastelloys, Inconel or Titanium alloys.

Flexible multilayer panels for thermal insulation and/or fire protection, indicated when the component

shape and movements need more parts connected with each other, usually used

to protect structural parts or air cooling systems.

They are especially suggested when complex shapes need the most

lightweight solution, with less upfront costs and lead time in

the development phase.

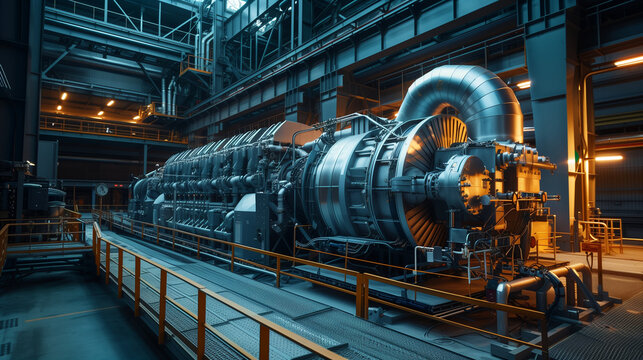

Rigid insulation panels for thermal insulation, typically used in gas and

steam turbines for the conservation of process heat or to protect

personnel and equipment. The insulation elements can be based

on customer’s drawings or custom designed by ITAI.

The insulation systems found in this category are made for the process pipes in

plants of the Oil&Gas sector, they can be made even with complementary heat

tracing cable systems, all designed and supplied by ITAI.

ITAI supplies a “turn-key” solution, for direct use on site

or, in alternative, ITAI can perform assemblies at the customer’s yard.

Typical materials: high performance insulation Microporous or Aerogel

type material is used only when reduced space does not consent to use

rock wool or other mineral fibers. These are the standard solutions and

they offer the best trade-off between insulation performance, ease

of installation and serviceability. The external metal jacketing (cladding)

is constructed in sub-millimeter metal foil: for common applications it can be

Aluminium or AISI 304 / 316 steel, but it can also be constructed in AISI 321 steel,

Hastelloys, Inconel or Titanium alloys for more demanding applications.

Thermal and/or acoustic insulation blankets, custom shaped for the installation

on steam and gas turbines, exhaust duct/manifold, centrifugal compressors

and their gearboxes.

ITAI supplies a “turn-key” solution, for direct use on site

or, in alternative, ITAI can perform assemblies at the customer’s yard.

Typical materials: rockwool or high temperatures AES

fiber wool are commonly used. The best performance insulation, Aerogel type material,

is used only when needed to reduce the envelope of the insulation system as

much as possible.

The external cover is constructed in PTFE or silicone-coated glass

fiber fabric. When the application is in a cryogenic environment, different materials

are used: specific Aerogel type material, elastomeric FEF type, cellular glass or

poliuretanic insulation; the external cladding can be made of metallic or polymeric

material as per technical requirements.

Thermal rigid fixed protection or removable heat shields, to be installed on

hot parts of engines, such as exhaust manifold, turbocharger’s turbine case

or complete exhaust systems.

These insulation systems are also used to protect from external heat sources

composite components or tanks and systems of flammable liquids, such as fuel and oils.

Typical materials: high performance insulation Microporous or

Aerogel type material. The best possible thermal abatement with reduced thicknesses.

The external metal jacketing (cladding) is constructed in sub-millimeter metal foil:

AISI 321 steel, Hastelloys, Inconel or Titanium alloys.

Used for the same purposes of the rigid solutions, they are

simpler and faster to design and construct, albeit with a lower

performance.

Typical materials: Silicon fabric and stainless steel mesh are the most commonly used.